The situation

Natural gas from gas wells are full of by-products that affects its safety and usability. Two such products are water and acid gases such as carbon dioxide (CO2) and hydrogen sulphide (H2S). Gas processing plants often use solvents such as amine and glycol to absorb these contaminants, thus removing it from the gas stream.

A solvent loop is set up, where the solvent first absorbs these by-products in the absorber, then releases it in the regenerator. It is essential that the solvent is free of contaminants such as particles and dissolved hydrocarbons, as

- Hydrocarbons and particles can cause foaming which reduces performance of the absorber

- Particles can cause erosion to piping and other equipment, reducing its lifespan

The system

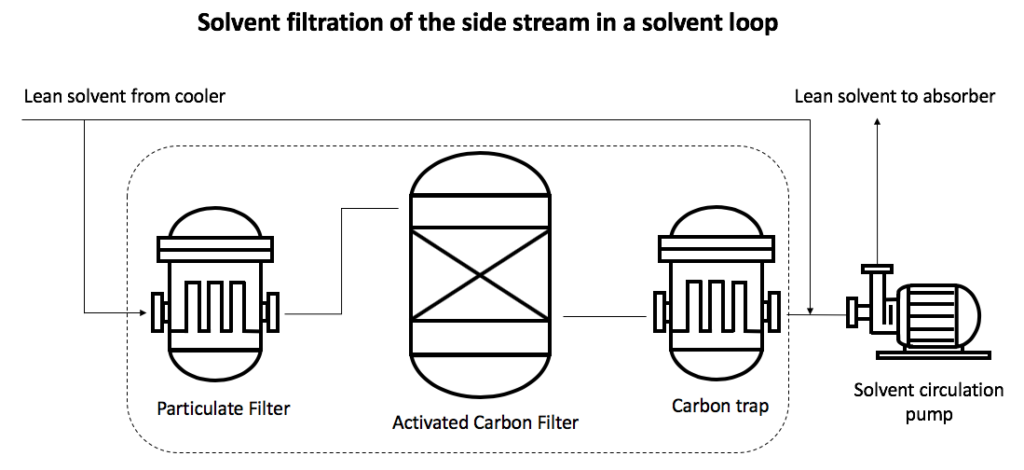

A typical system is as shown below:

Operators usually filter a 10% side stream of the chilled, lean solvent before it reenters the absorber. It involves the following:

- Particulate filtration to remove particles 5μm and above. This prevents blocking of the active sites on the downstream carbon filter

- Activated carbon filtration to remove dissolved hydrocarbons

- Particulate filtration to remove fine carbon dust from the activated carbon filter

These are usually run in a 2×100% configuration, to ensure availability during filter media changeout.

How we can help

We have a complete range of Filtrafine® filter cartridges and housings for this application. Typically, solvent loops in the oil and gas industry involves very high flow rates, due to the high throughput of natural gas. If you are having to filter a large amount of solvent, look no further than Filtrafine® high flow series filter cartridges. Some features, advantages and benefits can be summarised below.

Features

Wider (6") diameter cartridge with center core

Higher surface area per installed cartridge

Less cartridges installed per housing

Advantages

Lower pressure drop for the same flow rate

Smaller housing and less structural steel needed

Reduces plant personnel’s exposure to hazardous environments

Benefits

Decrease in pump duty and utility cost

Decrease in total footprint and capital cost

Increase plant safety and uptime

For more information check out the links below,

NHF Series High Flow Filter Cartridge

LHF Series High Flow Filter Cartridge

We’d love to hear your opinions, comments and thoughts so please feel free to comment below. If you would like us to work on your filtration issues, please drop us an email and we’d be happy to!

![]()