The situation

Steam is used in industries such as food and beverage, power and healthcare to sterilise equipment and production lines, to cook food, and to run turbines and heat exchangers. While steam is generally free of bacterial contamination, they can pick up debris, corrosion products and other particles from piping and other equipment upstream. Failure to remove these particles can cause the following issues:

- Reduced performance of downstream valves, heat exchangers, sterile filter elements by fouling and plugging

- Contaminated food and beverage from dirty steam resulting in costly and tedious product recalls

- Stained or rusted sterilised instruments from exposure to contaminated steam

Hence, steam filtration can go a long way to address these issues. The two main categories of steam are as follows:

- Process Steam

This is mainly for general heating applications, and where the steam is not in direct contact with the product. Process steam is used in steam turbines, steam jackets and for sterilising equipment.Here, steam is filtered down to 5 micron.

- Culinary Steam (aka Food-grade steam)

This is steam that comes into direct contact with food or food processing equipment. As such they are typically more stringent from a regulatory standpoint. 3A, Pasteurised Milk Ordinance and US Food and Drug Administration (FDA) are some of the regulatory bodies involved. In this application, 3A specifies a 95% retention of particles 2 micron and larger.

The system

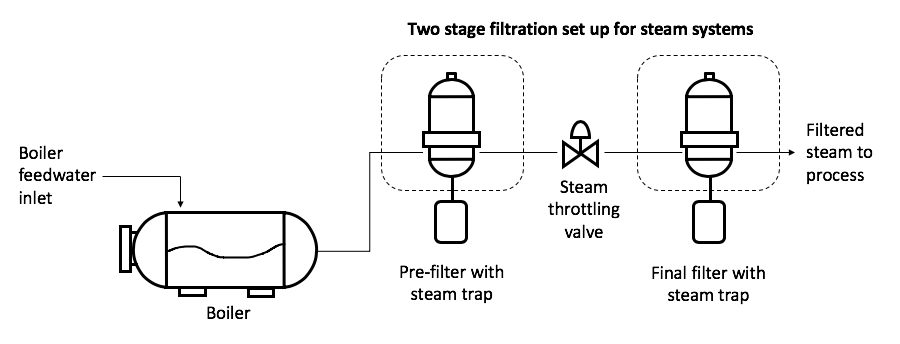

A typical steam filtration setup combines a pre-filter to remove larger particles, followed by a final filter. Steam traps remove any condensate present to prevent formation of potential damaging liquid slugs.

Certain older steam filter cartridges are made with borosilicate glass or granulated carbon. These can release fines or shed their fibers into the process, especially if they are subject to pressure surges. This degradation results in a lifespan of typically 4-6 weeks before replacement.

How we can help

Filter cartridges

Our Filtrafine® GSD-G filter cartridges are designed specifically for this application. These are fully stainless steel cartridges capable of surpassing 3A standards for culinary steam. Rest assure that they will not degrade or shed particles into your process.They can be regenerated with solvents or ultrasound, further prolonging its lifespan. You do not have to worry about compatibility as they are compliant to US CFR Title 21 requirements for food contact applications.

Filter housings

Filtrafine® has designed and manufactured filter housings for close to 20 years. In that time, they have developed a complete range of steam filter housings up to 16 bar and 232°C (450°F). No matter your plant requirements, we can make sure you are getting the right product that does the job.

For process steam or pre-filtration of culinary steam, we recommend the more economic GDV-R Steam filter housing with its electropolished/bead blasted finishing. For more sanitary applications, we recommend the GDV-S Sterile filter housing, which is made out of 316L stainless steel electropolished down to Ra32. Final filtration of culinary steam and certain pharmaceutical applications are some use cases for the latter.

For more information, you can check out the respective brochures below:

Filtrafine – GSD-G steam filter element-EN

Filtrafine – GDVS Sterile filter housing-EN

Filtrafine – GDVR Steam filter housing-EN

We’d love to hear your opinions, comments and thoughts so please feel free to comment below. If you would like us to work on your filtration issues, please drop us an email and we’d be happy to!

![]()